Safran USA and Albany Engineered Composites partnered in the 1990s to create innovative aerospace products. In 2012, their partnership yielded a new type of fan blade for airplane engines. Constructed of composite materials, the blade promised greater cost- and fuel-efficiency for the airplanes used by many carriers. Safran and Albany needed to develop a manufacturing site and acquire a workforce of hundreds in a short period of time to meet the expected demand. Meanwhile, Rochester, New Hampshire was actively trying to improve economic development opportunities for its citizens following the relocation of several industrial companies, and recognized Safran and Albany’s need as an opportunity to increase jobs in the area. In partnership with Great Bay Community College, under the leadership of Will Arvelo, city officials proposed that the companies build their manufacturing site in a state industrial park. They likewise proposed that by training students of Great Bay Community College, they could provide a certified workforce. This cross-sector partnership resulted in a manufacturing site for the fan blades and an advanced education and work-training curriculum in aerospace technology. One and a half years later, in June 2013, the Advanced Technology and Academic Center (ATAC) of Great Bay Community College welcomed its first cohort of students.

Creating a Technical Training Program in New Hampshire

About This Project

“We can’t do everything that we’re asked to do on our own… We need to be able to find connections, links, pathways to other organizations within our community that allow us to leverage resources.”— Will Arvelo, President of Great Bay Community College

Download this case study »

Will, the President of Great Bay Community College, brought the budgetary, technical, and educational facets of the collaboration together. His longstanding interest in partnerships between sectors to improve communities, combined with his background in both public policy and education, made him an asset to the effort. With skills garnered from a career in higher education, and a dedication to strengthening partnerships between businesses and educational institutions, he successfully oversaw the construction of ATAC and its training programs.

Transferable Skills

Will worked in higher education for 25 years prior to becoming the President of Great Bay Community College. He served as Benjamin Franklin Institute of Technology’s VP of Corporate and Community Relations, building relationships with external industries and learning how best to navigate their concerns, as well as successfully tailoring educational programs to workforce needs. With experience as a convener of workforce-training programs, Will applied his negotiation and communication skills to satisfy the needs of Great Bay, Albany Engineered Composites and Safran. Will also had previous experience in marketing partnerships effectively to businesses and appealing to their needs, as well as management of large construction projects: In 2007, he supervised the $15 million renovation of an ex-Air Force base hospital to provide a new space for Great Bay Community College.

Intellectual Thread

Will has long been interested in the power of collaboration and partnership, understanding that educational institutions could play a key role in the development and revitalization of communities. His doctoral dissertation explored the collaborative efforts undertaken by colleges and urban communities, showing how community colleges provide municipal initiatives by identifying available resources. Recognizing that a partnership isn’t always natural to educational institutions, he stressed the importance of creating a sense of “buy-in.” Will used this subject matter expertise when reaching out to the leaders of the City of Rochester, DRED, and Safran to explain the importance of including Great Bay Community College in the collaborative effort.

Contextual Intelligence

Will’s previous experience creating partnerships between colleges and private interests helped him understand how businesses prioritize achieving deliverables. As VP for Corporate & Community Education, Will created a partnership with CVS to develop a pharmacy technical training program and a lab facility. Will also created a partnership with the Optician’s Association of Massachusetts. There, too, he was able to appeal to the private sector’s need to find an educational institute to house an optician program. He credits the ability to follow through as crucial to working with outside industries and businesses. Will came to the collaboration between Great Bay, Safran, and Albany Engineered Composites with the ability to develop programming and partnerships that satisfy the needs of an external organization, delivering measurable results to the collaboration’s private partners.

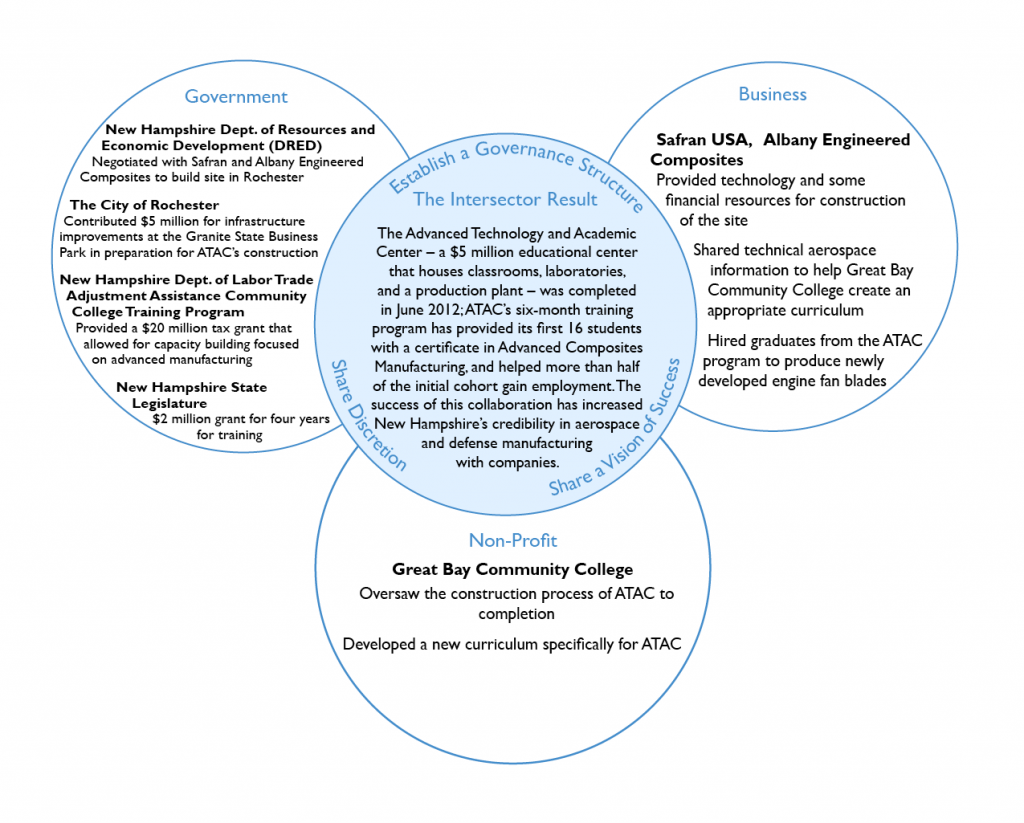

Share a vision of success

The goals of the collaboration were clear from the outset: to build a manufacturing site and training center, to maintain production levels by means of a qualified workforce, and to increase employment opportunities for Rochester citizens. A well-designed curriculum and training center helped Great Bay Community College continue their mission of providing useful, employable skills to their students. The government departments involved gained more visibility for New Hampshire and made it more attractive to outside industries. Safran and Albany have been successful in increasing production of their fan blade technology.

Share discretion

All parties wanted to be fully invested in the success of ATAC and its training programs. Safran, Albany Engineered Composites, and Great Bay Community College each played an equal role in deciding both the management and allocation of state funding and financial resources and program details. The partners also routinely revisited the curriculum for the center to monitor the ways in which it could be improved. Additionally, all changes made to the training program and curriculum were made collectively; no one entity held more influence in decision-making than the other, and partners learned to recognize the expertise each brought to the table.

Establish a governance structure

The collaboration used a fluid governance structure, which adapted as it progressed. At the curriculum design stages, there were formal meetings between Safran and Great Bay Community College to discuss the details of the project to ensure the responsibilities of each party were solidified. As each group became more trusting, communication improved. Monthly meetings between Albany Engineered Composites, Safran, Great Bay Community College and DRED continue, where they discuss potential changes to be made to the curriculum and laboratory equipment, the screening process for incoming students, the layout of the facilities, creating student-company engagement, and increasing enrollment and productivity to meet the companies’ needs. On a weekly basis, the program director from Great Bay Community College met with company engineers to discuss curriculum issues such as finding expert faculty and ensuring that training equipment is appropriate to training needs. Though final decisions about all aspects of the program are made by consensus, the partners play different roles in coming to decisions. Great Bay is in most direct contact with the day-to-day details of the program since they are the educational institute through which the curriculum is run. DRED plays a supportive role; they manage and advocate on behalf of the companies and to address the needs of the community college if necessary. The two companies lend their expertise in engineering, and in keeping up with the equipment needs of the courses.

Commit to information sharing

Because ATAC was Great Bay Community College’s first experience in this area of study, they depended heavily on Safran and Albany to provide technical knowledge to help design the curriculum as well as determine necessary laboratory equipment. The companies demonstrated trust in the collaboration and in the New Hampshire Community College system by sharing this restricted, valuable information. It was also important for the City of Rochester to offer its knowledge about the Granite State Park, where the construction occurred, including the necessary infrastructure developments.

Communicate the interdependency of each sector

The collaboration required that each sector have a clear understanding of how their participation was necessary to achieve the desired results. Great Bay Community College made it clear to the companies that they needed to be a part of the entire design and planning process. The companies’ participation was necessary to learn about the educational opportunities the partnership could offer, and to convey to students the benefit of attending ATAC. The role of the businesses was not just confined to funding the construction of the Center; they also were active in discussions about logistics and provided technical expertise to assist in the creation of the curriculum. DRED was essential in negotiations both to secure Rochester as the prime location for the center and to ensure continued long-term financial support for its training. Additionally, DRED helps to advocate for the needs of the companies to the state government.

The Advanced Technology and Academic Center (ATAC) has succeeded because of collaborative effort of Safran USA, Albany Engineered Composites, the state of New Hampshire, and Great Bay Community College. The six-month advanced engineering training program provides students the opportunity to specialize in eight different manufacturing engineering trades and awards certificates in Advanced Composites Manufacturing. ATAC helps the City of Rochester, and the State of New Hampshire as a whole, to position themselves as industry-friendly.

- The ATAC’s first cohort began with 18 students; Of the 16 students who graduated, eight were hired by Safran and the others were hired by other companies.

- The second cohort of students began in November 2013, with third and fourth cohorts beginning in February 2014.

- As the training program continues, Great Bay Community College plans to increase their enrollment numbers to 35 in 2014, 50-60 in 2015 and 200 in both 2016 and 2017.